Direct Metal Mastering (DMM) is a technique used in the mastering and cutting of vinyl records. It's an alternative to the traditional method of cutting vinyl records using lacquer discs. DMM was developed by two German companies, Telefunken-Decca and Georg Neumann GmbH.

In a world of ever-evolving music consumption methods, vinyl records have staged a remarkable comeback, offering audiophiles and music enthusiasts an authentic, warm, and tangible listening experience.

Amidst this resurgence, innovative techniques in vinyl production have emerged, one of which is known as Direct Metal Mastering (or DMM, for short). This cutting-edge technology has revolutionised the way vinyl records are created, enhancing their sound quality, durability, and overall appeal.

In this post, we delve into the realm of Direct Metal Mastering, unraveling its intricacies, benefits, and significance in the world of vinyl records.

So, What Is Direct Metal Mastering?

DMM is a vinyl production method that was developed by two German companies, Telefunken-Decca and Georg Neumann GmbH, using technology that had been used by RCA for their SelectaVision video discs in the late 70s. The technique was only really developed and utilised towards the end of the vinyl production period, which is why fewer records have been pressed using this method.

Before we dive into the specifics of Direct Metal Mastering, let's briefly review the basic process of vinyl record production. Vinyl records are analog audio storage mediums that rely on a physical representation of sound waves as grooves etched into a record's surface. These grooves are created using a master disc, a template that holds the audio information in a spiral groove pattern.

Did you know?

In traditional vinyl record mastering, the master disc, typically made of lacquer-coated aluminium, is cut with a stylus that engraves the grooves representing the audio signal. This lacquer disc is later used to create the stamper, which is used to press the vinyl records. While this process has served the industry well, it's not without its limitations.

Direct Metal Mastering, introduced as a significant advancement in the 1980s, seeks to address some of these limitations. Instead of using a lacquer-coated father plate, DMM employs a copper disc as the master. This copper disc is then coated with a photo-sensitive material. The audio signal is then directly engraved into this coated disc using a precision laser. Direct Metal Mastering shortens and simplifies the traditional pressing process, from three steps, down to just one.

Take a look at some more benefits of DMM below:

What are the Benefits of DMM?

Enhanced Sound Quality

One of the most compelling advantages of DMM is its potential to improve and define sound quality. The direct engraving process results in a more accurate representation of the original audio signal, translating to improved frequency response, better stereo imaging, and reduced distortion.

Durability and Longevity

Vinyl records created using the DMM process are known for their durability. The use of copper discs makes them more resistant to wear during the pressing process, resulting in records that maintain their sonic integrity over a greater number of plays.

Reduced Surface Noise

DMM records tend to exhibit lower surface noise compared to traditionally mastered records. The smooth surface of the copper disc and the absence of the intermediate lacquer layer contribute to a cleaner sound, allowing the listener to enjoy the music without distraction.

Precise High Frequencies

The laser engraving process in DMM allows for finer and more precise grooves, which is particularly advantageous for high-frequency information. This means that delicate details and nuances in the music, often found in cymbals, strings, and vocals, can be faithfully reproduced.

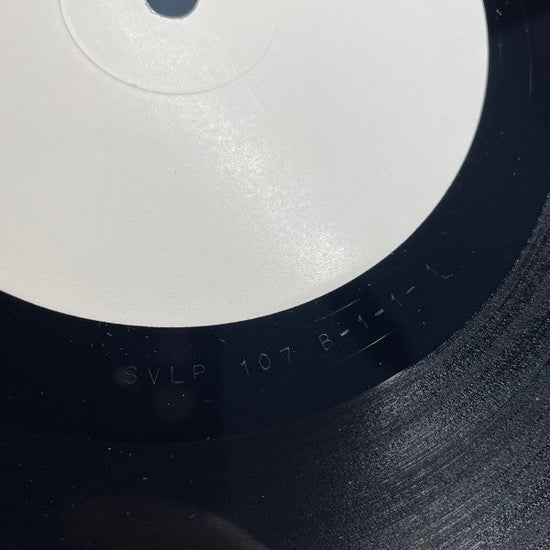

Now unlike many other record features, knowing that a particular release was pressed via DMM can sometimes be a little tricky to confirm. In some cases, a pretty noticeable DMM label will appear on a record’s sleeve-front or back, but in other instances, you will need to look at the record’s dead-wax space to see if it contains a ‘DMM’ stamp or etching.

So, just in case you were curious as to whether any of your own records were pressed using this technique, here is a list of some examples that were known to have utilised DMM in some of their pressings:

1. Iron Maiden - Somewhere In Time (1986)

This record is one of the more identifiable DMM pressings, as it may feature a distinct ‘Direct Metal Mastered’ stamp next to the record’s matrix numbers. We currently have a DMM pressing of this record available on our website, click here to see if it's still available!

2. Dire Straits - Brothers in Arms (1985)

This iconic album by Dire Straits is often cited as one of the early examples of records pressed using DMM technology. Known for its exceptional sound quality, "Brothers in Arms" showcased the benefits of DMM in terms of improved dynamics and clarity.

3. Metallica - Metallica (1991)

Also referred to as "The Black Album," Metallica's self-titled album was released using DMM technology. The album's heavy sound and dynamic range were enhanced by the DMM process, contributing to its lasting impact.

4. Pink Floyd - The Division Bell (1994)

This Pink Floyd album is another example of a release that benefited from DMM technology. The atmospheric and intricate soundscapes of the album were well-suited for the improved sound quality offered by DMM.

5. The Beatles - Vinyl Reissues

Some reissues of The Beatles' albums in the 1990s were known to have been pressed using DMM. These reissues aimed to preserve the original sound while taking advantage of the advancements in vinyl production.

6. David Bowie - Vinyl Reissues

Similarly, some reissues of David Bowie's albums, particularly in the 1990s and early 2000s, utilised DMM technology. Bowie's diverse musical styles and production techniques were showcased through the crisp audio quality of DMM records.

7. Neil Young - Vinyl Reissues

Neil Young's albums, including classics like "After the Gold Rush" and "Harvest," have been reissued using DMM technology to capture the nuances of his folk-rock sound and distinctive voice.

It is worth in mind that the availability of DMM-pressed records can vary depending on the edition, release, and geographic location. The examples provided above highlight some well-known instances where DMM technology was used to enhance the vinyl listening experience.

As the vinyl revival continues, Direct Metal Mastering remains a shining example of how blending traditional techniques with cutting-edge technology can result in a harmonious marriage of nostalgia and progress.

Whether you're a seasoned audiophile or a newcomer to the world of vinyl, the allure of DMM records is a testament to the enduring magic of analog music.

So, the next time you place that carefully crafted vinyl on your turntable, take a moment to appreciate the intricate artistry of Direct Metal Mastering that allows the music to come alive in ways that resonate with both the past and the future.